Sustainable agriculture

Sustainability and Martignani sprayers

Over the last few decades, working in agriculture with a sustainable approach has become an absolute priority for everyone involved.

By sustainable agriculture, we mean agriculture that respects the environment and natural resources in such a way as to work the land today without jeopardising the future of the next generations.

Agriculture, by its very nature, has a significant impact on the environment, and in this historical period, water scarcity, deforestation and climate change are issues on the agenda. A model of cultivation and agricultural development that seeks to provide for the sustenance of the population while simultaneously minimising the impact on the planet can make a difference.

For this reason, Martignani has always sought to design and produce high performance agricultural machinery to promote the sustainable use of plant protection products and water saving.

Let’s discover how Martignani’s agricultural sprayer technology can fit perfectly into the logic of sustainable agriculture.

“Our mission is to ensure access to healthy food and promote the viability of agriculture today and for future generations.

We do this through integrated research, education, communication and early action on major emerging issues.”

Agricultural Sustainability Institute

Martignani, low volume, micronisation, electrostatics and product recovery

Combining proper droplet micronisation and electrostatics, MARTIGNANI pneumatic sprayers offer remarkable efficiency in terms of spray quality and drift reduction.

Founded in 1958 in Lugo di Romagna, Martignani never stops innovating for the greater benefit of wine and fruit growers.

Low volume in Martignani sprayers

Martignani has always focused on innovation with a crucial objective: to optimise the quantity of product deposited on the target by limiting possible drift.

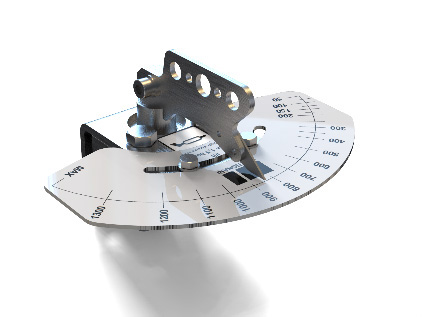

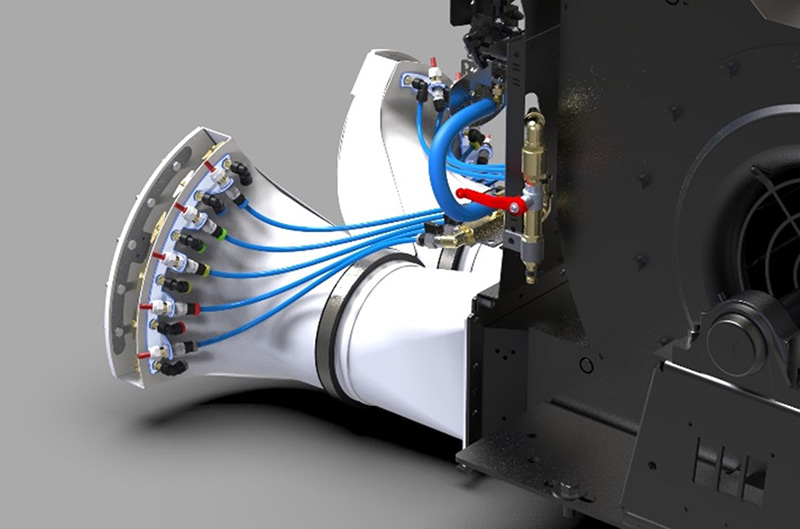

Thus was born the Low Volume with a system for the correct micronisation of droplets based on a technology that combines centrifugal fans with high aerodynamic efficiency, high flow rate centrifugal pumps, precision mechanical metering valves and pneumatic wing nozzles with wide passage.

This system makes it possible to control the volume deposited

on the rows to be treated; the pneumatic wing nozzle with large passage fins (as much as 4 mm) ensures perfect distribution and micronisation of all products, from the most fluid to the most concentrated, without any risk of occlusion or wear over time.

For several years, this technology has also been ideal for spraying kaolin on olive trees or any other clay product, including basalt dust, zeolite, etc., for organic farming.

Electrostatics in Martignani sprayers

The other innovation implemented by Martignani, which integrates pneumatic micronisation, is based on electrostatics (the FIRST sprayer manufacturer in the world to implement this in 1981 and the ONLY one to have been tested multiple times with DOCUMENTED results).

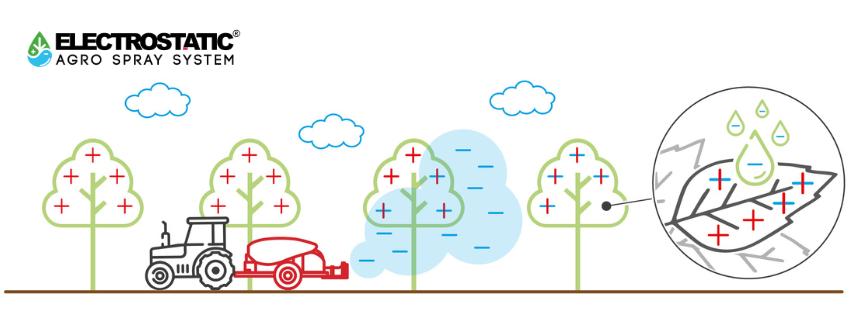

This process consists of negatively charging the product droplets, improving their ability to adhere to the vegetation and settle on the underside of the leaves, which are not directly exposed to the spray. This process is commonly used in industrial painting.

The results of technical tests on Martignani sprayers

These performance levels are further demonstrated by two recent studies by an Inter-professional Technical Centre for Fruit and Horticulture in France (CTIFL Sciences & Innovation).

STUDY No.1

Comparison of drift generated by pneumatic wing nozzles and air injection nozzles (also known as “anti-drift”)

Case of the Martignani Whirlwind TURBO 2 sprayer equipped with both pneumatic wing nozzles and anti-drift

These studies compared the drift levels obtained with a Martignani Whirlwind TURBO 2 sprayer in its standard pneumatic configuration fitted with a pneumatic wing nozzle, with an identical prototype also equipped with air injection nozzles (anti-drift).

The conclusions indicate that:

“…in disturbed wind conditions (gusty wind, wind direction not perpendicular to the reference zone), the use of anti-drift nozzles is of no interest and even generates, at 5 and 10 m from the last row, more drift than Martignani’s pneumatic wing nozzles. Under more favourable conditions, the measurements between the version with pneumatic wing nozzles and the version with anti-drift nozzles are similar.”

STUDY No. 2

Analysis of the impact of electrostatics on application quality

The case of the Martignani Whirlwind TURBO 2 sprayer equipped with pneumatic wing nozzles and electrostatic device.

The conclusions indicate that:

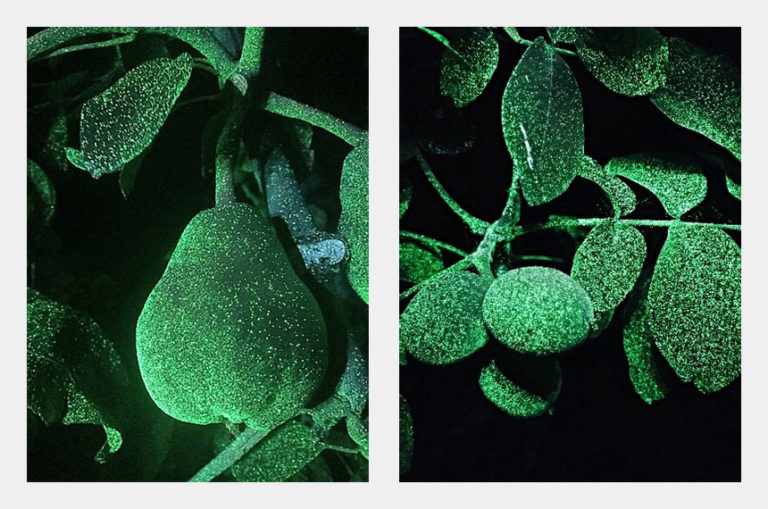

“Under the conditions of this test, and according to the methodology implemented and described in this report, the use of the electrostatic system on the Martignani pneumatic sprayer model Whirlwind TURBO 2 generates significantly greater droplet deposits on the treated row than the same sprayer without electrostatics.”

The electrostatic system significantly increased product deposits by 67%.

The effect of attracting the charged droplets to the plant is also noticeable in the opposite wall of the plant (i.e. the wall not directly treated by the sprayer): “…with the electrostatics, the sprayed droplets are attracted back to the vegetation inducing significantly higher deposits”.

Tests have shown that electrostatics can increase spraying efficiency by 67% compared to systems without it.

These studies (available on request) were carried out on orchards in September and October 2021 at Lanxade – 24130 Prigonrieux (France).

Conclusions

From these field tests, it is easy to understand that the air injection nozzle (also known as the “anti-drift” nozzle) is NOT the solution for reducing the so-called drift in the environment, far from it.

Martignani’s pneumatic spraying system with electrostatic charge recovery combined with a correct configuration of the spray heads, which in the pneumatic system conduct the air current that generates the droplets and transports them to the target and the correct droplets size (100 to 200 microns), still represents the most EFFECTIVE, SIMPLE and RELIABLE system over time for protecting crops while respecting the environment and operators.

The complex systems with recovery panels, for which the criticalities caused by the recirculation of off-target chemicals and the complex maintenance they require are well known, have become necessary to limit the effects caused by the considerable run-off (30 – 50 %) and the drift into the environment (10 – 15 %) from traditional spraying systems with mechanical spray nozzles or air blast sprayers.

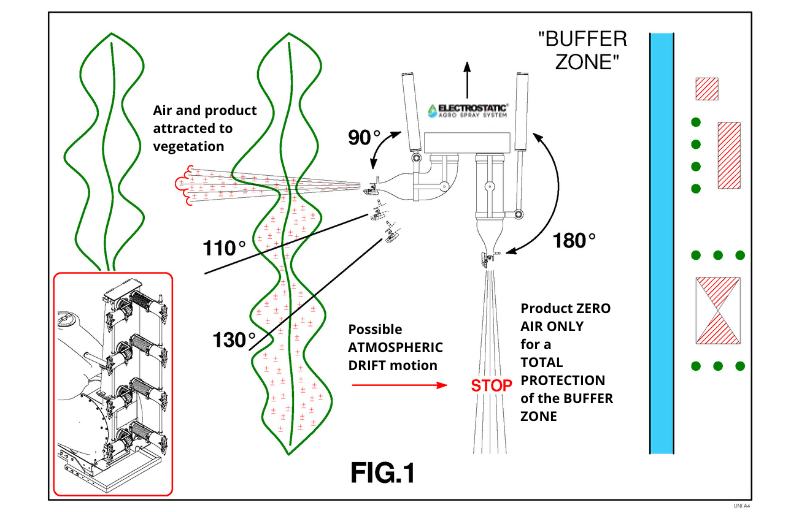

As an alternative to this type of recovery screen machines, Martignani, for the so-called “buffer zones”, offers two solutions for viticulture and fruit growing.

For viticulture

The panel model with anti-drift lamellar air cushion (European Patent No. EP 2689662 A1) Whirlwind M612 “Duo-Wing-Jet”

For fruit growing

The Whirlwind M612 sprayer with “Mutliflow-Orchard” configuration, also called “Sudtirol” (European Patent No. EP 3087835) with turret and protection air curtain system already tested with total anti-drift results by the Edmund Mach Foundation/Agricultural Institute of S. Michele all’Adige (Trento) in 2016:

For further information or to receive copies of the tests mentioned above, please write us an email indicating as the object “MARTIGNANI and SUSTAINABLE FARMING” and forward it to marketing@martignani.com

MARTIGNANI