Electrostatic low volume

What is different about Martignani’s agricultural sprayers?

Discover the advantages of electrostatic spraying used by our machines.

Conventional spraying

The Martignani electrostatic spraying method features a different working system from conventional spraying (Normal Volume) based on high pressure nozzles with reduced diameter (< 2 mm.), where high water pressures (up to 40 bar/580 psi) are used with the use of an axial fan which “helps” the droplets to reach the target.

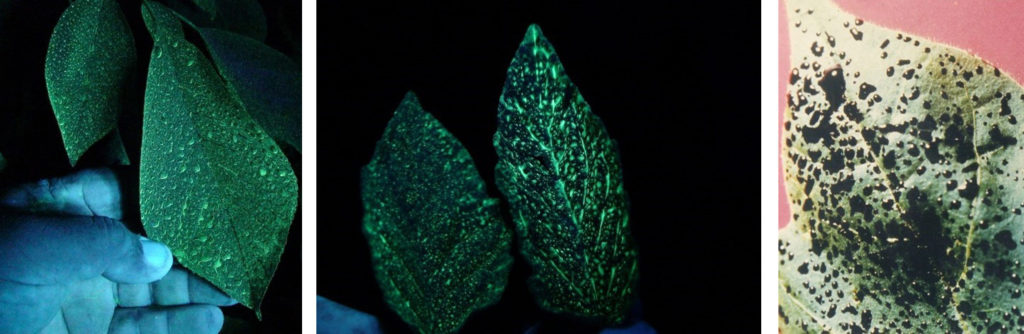

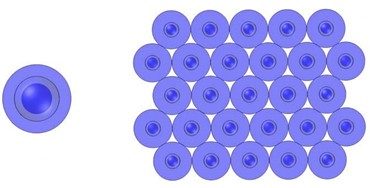

Once the treatment or spraying has been carried out with an AIR BLAST sprayer, particles with very different diameters will be seen on the target.

Martignani pneumatic-electrostatic spraying

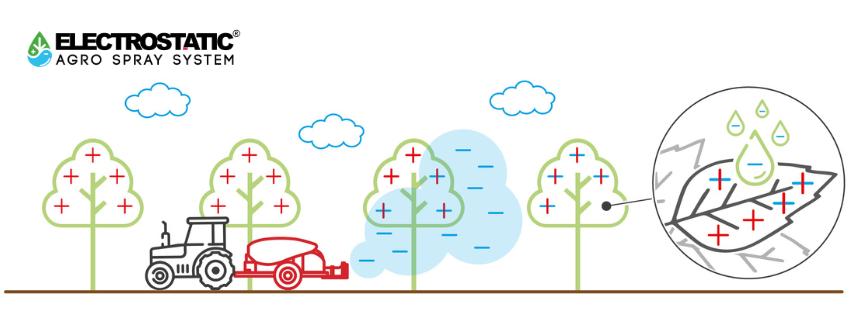

The essential feature of Martignani electrostatic spraying is the coverage on the target using separate, uniform droplets of a constant precise diameter. This system is based on centrifugal high efficiency fans and on target air ducts; where pneumatic wing nozzles of large diameter (4 mm) are inserted. The liquid, at low pressure (1,5 bar/22 psi), is sprayed by the air jet at high speed and is negatively charged, creating an electromagnetic field between the chemical mist and the plants.

The vegetation then attracts the droplets, preventing the drift in the environment and increasing the level of coverage and uniformity.

Once the treatment or spraying has been carried out with a Martignani electrostatic sprayer, you will notice very fine particles on the target that are well defined and evenly distributed (charged droplets of the same sign – negative – repel each other).

Good plant protection is obtained when 10% to 20% of the total surface is materially covered by droplets.

Droplet size: why it matters

The size of the droplets is not always of great interest to the user.

For MARTIGNANI, however, it is essential to carefully ensure that the jets or outlets of its sprayers produce droplets of optimal size and uniformity over time (varying between 60 and 200 microns depending on the selected target).

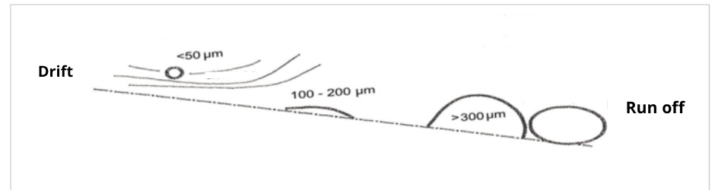

In fact, droplets that are too large are not advantageous because they represent more volume but allow only a tiny amount of coverage; moreover, these droplets often fall off before they have had a chance to reach the highest or most hidden parts of the tree and are subject to run-off (RUN-OFF or SOIL DRIFT or ENDODRIFT).

Droplets that are too small do not settle but remain in suspension in the air for too long transported by currents and drift away from the plants, or evaporate rapidly (DRIFT or AERIAL DISPERSION or ESODRIFT).

The following table gives an idea, depending on the diameter OF THE WATER DROPLETS, of what the evaporation times are, how fast they fall and how far they travel before evaporating. It is easy to understand, from this table, how, with a Martignani electrostatic sprayer, it is possible to operate even at very high temperatures without running into evaporation problems (for example, a 125-micron droplet takes a good 27 seconds to evaporate at a temperature of 30°)

Temperature 30 °C – Relative humidity 50%

| Diameter | micron | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | 325 | 350 | 375 | 400 | 425 | 450 |

| Water droplet lifetime | Seconds | 1 | 4 | 10 | 17 | 27 | 38 | 52 | 68 | 86 | 106 | 128 | 153 | 179 | 208 | 239 | 271 | 306 | 343 |

| Fall distance | Metres* | 0.01 | 0.2 | 1 | 3 | 6 | 13 | 24 | 41 | 65 | 99 | 146 | 206 | 284 | 382 | 503 | 651 | 830 | 1043 |

| Theoretical fall speed | m/s** | 0.1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | 1.1 | 1.2 | 1.3 | 1.5 | 1.6 | 1.7 | 1.9 | 2.0 |

* 1 mt=3,3 ft

** 1 m/s=3,3 ft/sec

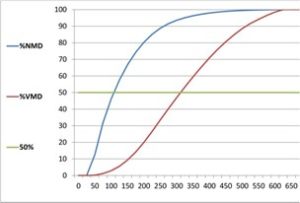

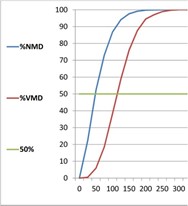

Extensive research into this problem has shown that the irregularities in the droplets produced cause as much as 50% of all the chemical product (VMD) sprayed to be often conveyed by just 5% of the larger sized droplets (NMD) distributed.

“DISAFA” test 2011 - Turin

MARTIGNANI

Low volume, micronisation, electrostatics

and product recovery

using a Martignani agricultural atomiser.

Basic principle of the Martignani pneumatic system

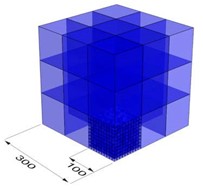

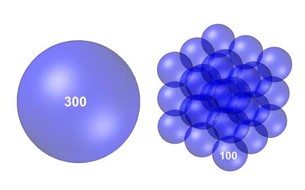

Let us compare a cube having a length, width and height of 300 micron (micron = one-thousandth of a millimetre) and a cube having 100 micron laterally. If the 300 micron cube is divided by the 100 micron cube, the latter is contained in the first cube three times as regards length, width and height, i.e.: 27 times, since 3 x 3 x 3 = 27 (Fig.1).

This rule applies not only to cubes but also to spheres and, therefore, to droplets (Fig.2).

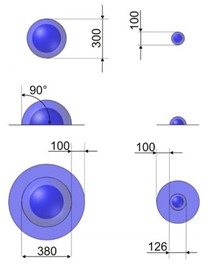

Around each droplet there is an area of 100 micron called Fleming’s halo, in which the active principle has effect. If we now compare the covered surfaces having the same volume, taking also into account the droplet squashing effect (Fig.3), we can notice the difference between the 2 covered surfaces which is considerably wider, approximately 10 TIMES wider (Fig.4).

This eloquent comparison makes it easy to understand why a “MARTIGNANI” sprayer provides better coverage, saving over 30% of chemicals and over 90% of solution water.

Fig. 3

Optimum droplet size range for selected targets

Droplet values in µm (microns)

Find out what differentiates a Martignani agricultural sprayer from a classic atomiser

Want to know more about our sprayers?

Write to us to tell us about your needs and find the suitable atomiser for your crop